Bag Sealing Equipment

Industrial Plastic Bag Sealers

Our bag sealing equipment includes sealing solutions for large Tote Bags with liners, paper/poly woven, BOPP woven bags, pinch style bags, hot melt adhesive bags, hot air activated glue strip open mouth bags, pinch inner liner bags, and every type of coextruded barrier or non-barrier plastic / poly bags. The industrial bag sealers we offer are known for their durability, compact design, innovative features, and can be easily integrated into semi-automated and fully automated bagging lines.Slider Zipper Bag Sealer / Pactiv Zipper Bag Sealer

Elevation offers an automatic Slider Zipper Bag Sealer or sometimes referred to as Pactiv Zipper Bag Sealer. This Continuous Band Sealer is specifically manufactured to address the challenges of bag sealing equipment for Slider Zipper bags or Pactiv Zipper Bags.

The Sealer is setup in such a way that it will weld the opposing side of Slider Zipper Bags or Pactiv Zipper Bags.

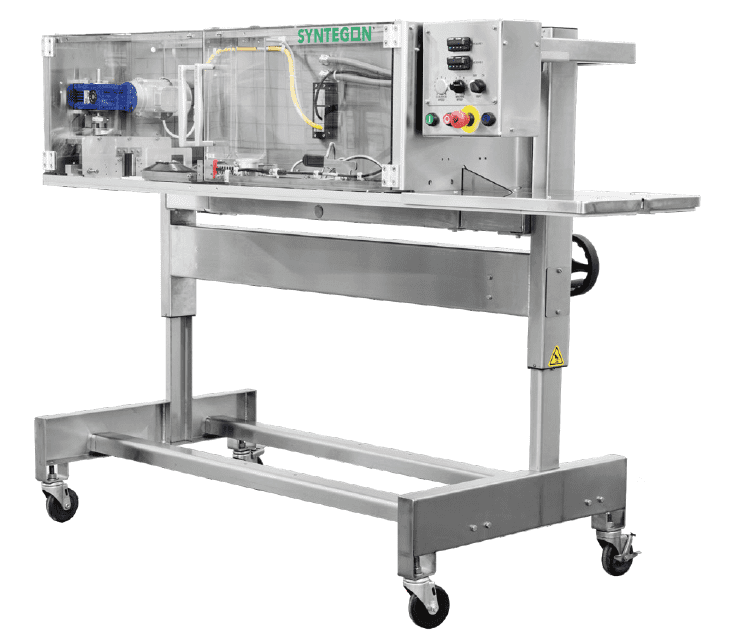

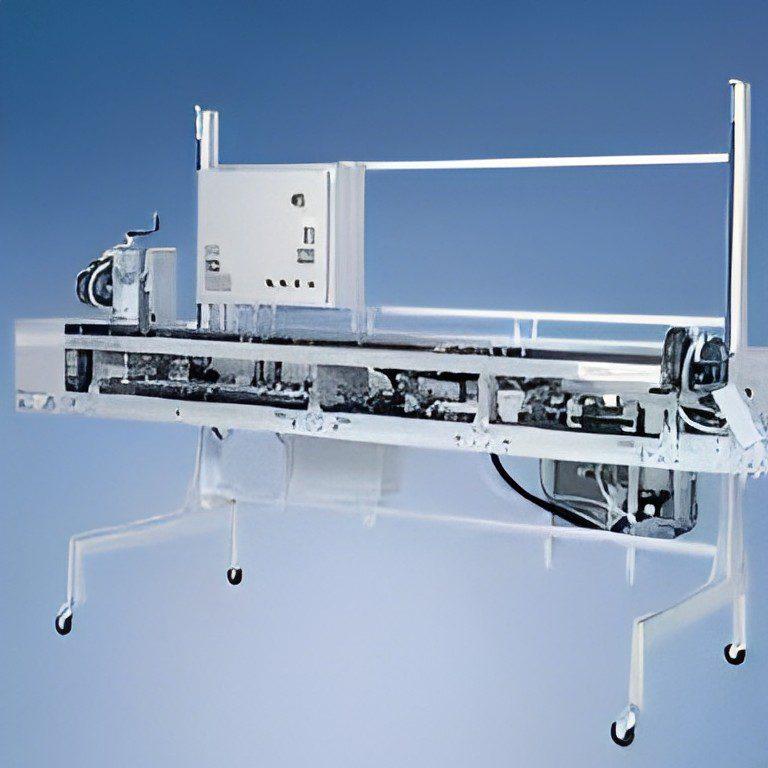

Syntegon CBS-D 1500 High-Quality Continuous Band Sealer

The CBS-D 1500M comes standard with two pairs of thermostatically controlled, 7.5” (190mm) long, precision machined aluminum heat bars coated with a super hard (57 Rockwell™) surface and two pairs of PTFE-coated, fiberglass sealing bands.

The CBS-D 1500M is supplied with stainless steel guards, top cover and electrical enclosure. The standard floor stand will be *304 stainless steel. All non-painted parts will be plated.

View the CBS-D 1500 Datasheet for more detailed info.

Get Started

Syntegon Band Sealers

Band Sealers can seal wide range of heat sealable films. Although used primarily for soft films (polyethylene), also known as unsupported films, they can be used on certain hard films (supported or high-density films such as polypropylene) and specialty films.

Band sealer speeds are considerably faster than intermittent types of sealing and perform well on various bag styles including gusseted. Syntegon Technology is launching its new, redesigned continuous band sealer machine range. The Doboy CBS-D and B-550 not only have new names – CBS-D 1500 and CBS-D 750, respectively – but feature improved operability in combination with the proven technology of their predecessors.

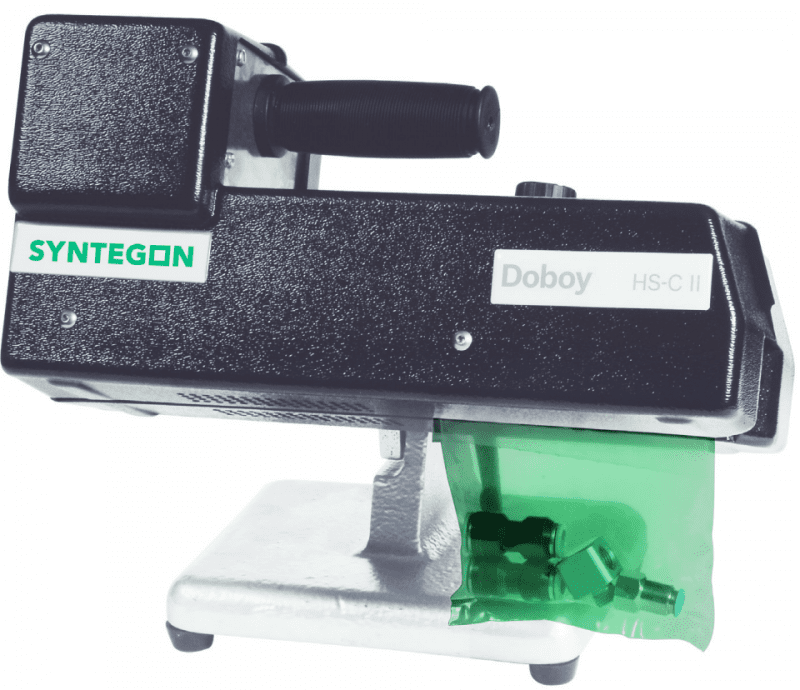

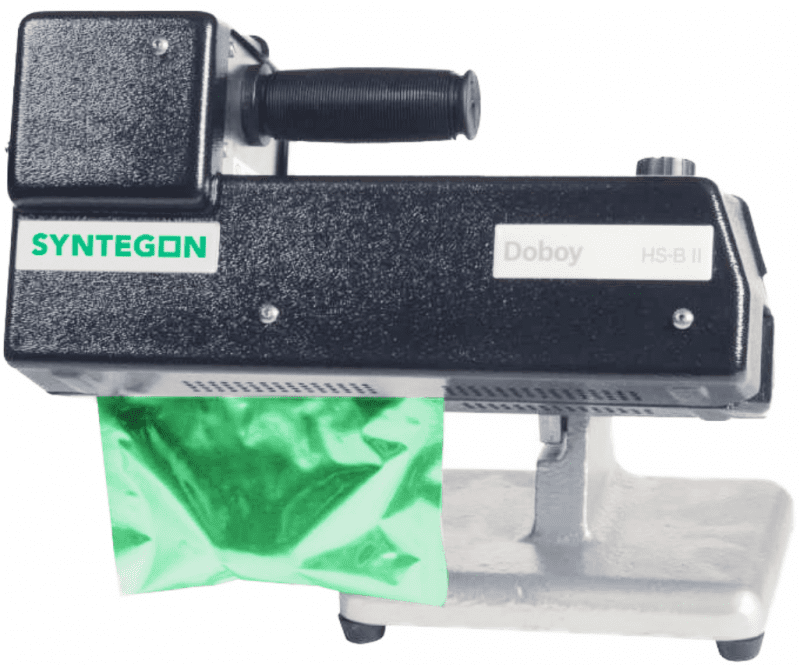

HS-BII - Portable Rotary Sealer

The HS-BII Rotary Sealer dependably seals supported films such as cellophane, glassine and paper laminates. The timing belt assures positive grip of material for clean, attractive closure. The HS-BII-V provides continuous sealing, quiet operation and is a variable speed unit from 0 to 250 inches per minute.

View the Doboy HS-BII Series Portable Hand Sealer Datasheet for more detailed info.

Get Started

Syntegon Woven Poly Bag Sealing

Woven polypropylene bags have been used as an alternative to burlap or paper bags for many years and have been typically closed with sewing machines. Sewn bag tops contain holes which are an avenue for infestation and moisture to enter the bag contents.

Syntegon recognizes that this has long been an industry problem. Building on over 70 years of industry experience, Syntegon now offers three machines designed to seal woven polypropylene bags:

- Double fold and glue

- Double fold and tape

- Conventional heat seal.

TFT Produces a Double Fold and tape closure at High Speed

The TFT Sealer trims, folds and tapes to provide a sturdy seal on woven poly bag material. Designed to package bulk products with a high integrity sealing method, the TFT operates up to 150 FPM. Applications include fertilizers, resins, titanium dioxide, garden products, agricultural chemicals and many others. The TFT has been constructed to provide many years of efficient production in even the toughest environments.Get Started

Syntagon Glue Sealers

Glue Sealers are intended to seal paper bags. We offer two fold styles: A double loop fold and a triple or square top fold. These two fold styles provide a secure closure and prevent product sifting. The double fold produces a strong sift-proof closure that is popular for a wide variety of consumer products.

Glue Sealers offer high speed closing and are typically incorporated into a fully automatic bag liner. Speeds up to 100 bags per minute are obtainable.

GS-1000S Double Fold Glue Sealer for High-Speed Production

Syntegon’s most advanced bag gluer, the GS-1000, is the logical choice when high-speed packaging production is required. With sealing capacity of up to 75 bags per minute, the GS-1000 is ideal for any automatic packaging line. The GS-1000 features a patented sealer folder design that is virtually jam proof. The fully adjustable folders are spring-loaded and manufactured from plate steel for rugged dependability.Get Started

Syntegon Pinch Style Sealers

Pinch Style Sealers close multiwall paper bags with product weights from 20-100 lbs. A pinch style bag features a stepped end to expose the plies of a multiwall bag. Hot melt is pre-applies by the bag manufacturer. The final closure involves reactivation of the hot melt and folding the stepped end over to bond with the face of the bag.

Pinch style bags may also feature a separate inner liner that is heat sealed in addition to the pinch closure. This results in a hermetically sealed bag and is commonly used in toxic products that are hydroscopic.

Syntegon Bag Top Labelers

With fast and simple set-up, Syntegon Bag Top Labelers reduce waste and provide flexibility and user friendliness.Pack 101 Flow Wrapper – Speeds up to 150 packages/min.

The Pack 101 horizontal flow wrapper is an entry-level wrapper that offers the widest product size range currently available on a flow wrapper in its class. It replaces Syntegon’s former entry-level wrapper, the Doboy Stratus, and offers improved flexibility and user friendliness. It is ideal for small- to mid-sized businesses needing a flexible solution that accommodates multiple products.The all-electronic control of the Pack 101 wrapper’s motors and drives, enables quick and easy setup and changeovers, reduces product and film waste during production, and offers low maintenance costs. It shares production-proven technology applied on Syntegon's higher-end flow wrappers. This flow wrapper furthermore reduces spare parts inventory and lowers the total costs of ownership for customers who wish to scale up with Syntegon's Pack series flow wrappers. Local manufacturing in the USA ensures speedy delivery and a fast service response. to customers in North and Latin America.Get Started

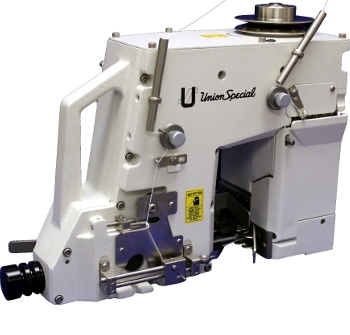

Union Special Bag Closing Equipment

Elevation Packaging is proud to offer bag sealing equipment from Union Equipment.

Union Special Bag Closing Systems – US400 Universal

- Universal Sewing System for Tape or Plain Sew

- BC211U__ series head with Guillotine Cutter

- PLC controls for start/stop and controlling tail length

- Heavy Duty Steel Pedestal equipped with Casters so its moveable.

- Fast! up to 75 ft/min

- Significant Tape Reduction with use of Guillotine Cutter

- Optional VFD on Sewing Head and Infeed

- Optional Tape Pre-Feeder for PP Tape or Higher Speeds

Get Started