Robotic Palletizers

If you are looking to automate your Bagging or Manufacturing process, we can help.

Palletizer Robot Options

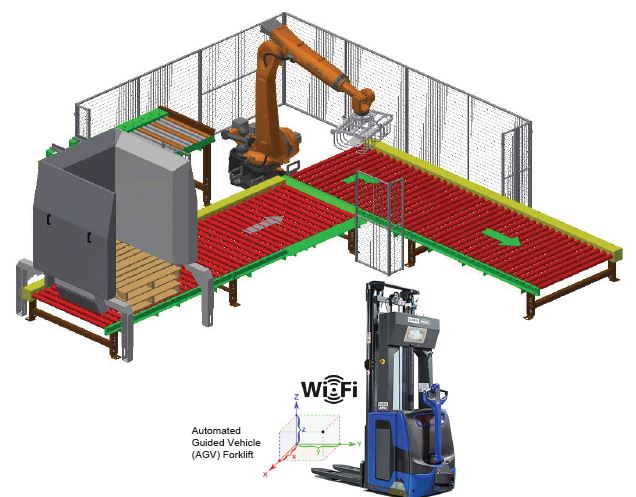

Whether it is upgrading an existing Robot with a new touchscreen providing Easy Pick Recipes, utilizing one of our standard Robotic Palletizing space saving cells, or implementing a mobile Robot for CNC Tending, we can help customize and integrate into existing equipment.

Kuka Robots

We offer many robotic palletizers and feel that Kuka provides the widest range of Robots from small Collaborative Robots (LBR iiwa Series) to Kuka Palletizing Robots including the very fast 5 axis Kuka KR 40, Kuka KR120 and next generation 2023 Kuka KR140 Robots. In addition to new robots, we offer reconditioned and/or used robots to help with budget constraints.Robot Pallet System Design

We have been able to design Robot systems that require very little space and are affordable. We can provide refurbished Robots with our own custom End of Arm Tooling that we build in-house and that fits within your budget. We also offer in-house financing with approved credit or can direct you to a financing company if you would rather have the options for a lease to own Robot Palletizer.

We have several videos below showing a variety of systems in action. Each Automatic Palletizing System has the ability to expand off of one of several base Robot cell designs.

Get Started

Contact us today at (402) 999-0827 or info@elevationpkg.com today to find out how your operation can benefit from an Automated Guided Forklift.

Or complete the form below and we will reach out to you.

Get Started

Contact us today at (402) 999-0827 or info@elevationpkg.com today to find out how your operation can benefit from Robotic Palletizers.

Or complete the form below and we will reach out to you.

5 axis KUKA KR120 Fully Automated Bagging Line with Dual Zone Palletizing

Watch a fully automated bagging line with a high-speed Kuka palletizing robot capable of running at 15-20 bags per minute (bpm).

The Kuka KR120 or Kuka KR140 Palletizing Robots complement any fully automated bagging line. The robotic arm will pick up individual bags from a supplied Stage and Pick conveyor and place them on a pallet with multiple pre-programmed recipes. It can handle up to 20 bags per minute or stack up to 1200 bags per hour.

We provide Fully automatic bagging systems including single or double / duplex Net Weigh Scales, auto Bag Placers which place empty bags on spouts to be automatically filled, Bag Reformer, Sewing Systems or Heat Sealers, any necessary conveyors including bag knockdown/turners, 90 degree bag kickers, bag Flattening Conveyors as well as fully automatic Pallet and Slip Sheet Dispensers that can feed finished pallets into an automatic stretch wrapping system.

Get Started

5 axis KUKA KR120 Fully Automated Bagging Line with Dual Zone Palletizing

Watch a fully automated bagging line with a high-speed Kuka palletizing robot capable of running at 15-20 bags per minute (bpm).

The Kuka KR120 or Kuka KR140 Palletizing Robots complement any fully automated bagging line. The robotic arm will pick up individual bags from a supplied Stage and Pick conveyor and place them on a pallet with multiple pre-programmed recipes. It can handle up to 20 bags per minute or stack up to 1200 bags per hour.

We provide Fully automatic bagging systems including single or double / duplex Net Weigh Scales, auto Bag Placers which place empty bags on spouts to be automatically filled, Bag Reformer, Sewing Systems or Heat Sealers, any necessary conveyors including bag knockdown/turners, 90-degree bag kickers, bag Flattening Conveyors as well as fully automatic Pallet and Slip Sheet Dispensers that can feed finished pallets into an automatic stretch wrapping system.

Get Started

Fanuc Robotic Palletizers

Watch three refurbished M410iB robots using our ultra-lite End of Arm Tool (EOAT) palletize a wide range of products.

The Fanuc M410iB or newer generation Fanuc M410ic robots can be setup to use a combination of vision technology, sensors and advanced software to perform a variety of tasks, including picking up bags, boxes and/or pallets and slip sheets.

This robotic palletizer can handle a wide variety of materials, including:

- glass bottles

- cans

- plastic containers

- paper rolls

- cardboard boxes

- bundled water bottles

- shrink-wrapped items

- large metal drums.

It can also handle a wide range of product sizes.

Get Started

Fanuc Robotic Palletizers

Watch three refurbished M410iB robots using our ultra-lite End of Arm Tool (EOAT) palletize a wide range of products.

The Fanuc M410iB or newer generation Fanuc M410ic robots can be setup to use a combination of vision technology, sensors and advanced software to perform a variety of tasks, including picking up bags, boxes and/or pallets and slip sheets.

This robotic palletizer can handle a wide variety of materials, including:

- glass bottles

- cans

- plastic containers

- paper rolls

- cardboard boxes

- bundled water bottles

- shrink-wrapped items

- large metal drums.

It can also handle a wide range of product sizes.

Get Started

Robotic Palletizing Cell With Auto Feed Pallet Magazine

In the first portion of the video, watch a Reconditioned Fanuc Robot palletize in two zones. When zone 1 is complete, the robot automatically switches to zone 2 while simultaneously sending a signal to the forklift operator letting them know a completed pallet is ready to be stretch wrapped.

In the second portion of this video, watch a modular Fanuc robotic palletizing system with our custom tandem end effector running at 15-20 bags per minute (bpm} interfacing with an automatic Pallet and Slip Sheet Dispenser.

The robot uses sensors to detect two bags on the stage and pick conveyor picking both bags up at the same time. Our Tandem End of Arm tool has two, independently operated End Effectors built on one main frame. This particular program is set up to place bag seals on the inside. When a pallet is complete, the Robot activates the pallet conveyor to move a completed pallet out of the palletizing zone while also activating the Pallet and Slip Sheet Dispensers to feed an empty pallet in.

Get Started

Robotic Palletizing Cell With Auto Feed Pallet Magazine

Watch a reconditioned Fanuc robot using our standard clam shell Ultra-lite end-of-arm tool to palletize 50lb bags of feed.

This is one of our more common and standard “Dual Zone” Robotic palletizing systems. The robot will continue to palletize, rotating from zone 1 to zone 2 and back to zone 1 as Operators are notified that a pallet is completed by way of our indicator stack lights. We provide a remote access module that interfaces with the use of multiple light curtains along with safety software and programming to allow forklift operators access to remove a finished pallet while the Robot continues to palletize on the opposing zone while keeping a virtual door closed to prevent access into the active palletizing zone.

Get Started

Automatic Palletizing with Safety Light Curtain Access

Watch a reconditioned Fanuc robot using our standard clam shell Ultra-lite end-of-arm tool to palletize 50lb bags of feed.

This is one of our more common and standard “Dual Zone” Robotic palletizing systems. The robot will continue to palletize, rotating from zone 1 to zone 2 and back to zone 1 as Operators are notified that a pallet is completed by way of our indicator stack lights. We provide a remote access module that interfaces with the use of multiple light curtains along with safety software and programming to allow forklift operators access to remove a finished pallet while the Robot continues to palletize on the opposing zone while keeping a virtual door closed to prevent access into the active palletizing zone.

Get Started

Automatic Palletizing with Safety Light Curtain Access

Watch a Fanuc robot with EML-Tech Ultra-lite end-of-arm tool palletizing feed.

This automatic palletizing system prevents operators from being injured when handling products on the conveyor belt by using a safety light curtain. It also features a high-speed camera which allows the operator to see where the robot is going and how fast it is traveling. This helps avoid collisions and keeps the robot on track.

Get Started

Robot Palletizing Wire Spools

Watch a Fanuc 420iF robot palletize wire spools with a Slip Sheet Pick and Place option.

The robot uses one of our custom-made End of Arm Tools with a slip sheet pick up option. We use a series of sensors to detect the spool and place them on a pallet. After a layer of wire spools are placed, the robot will pick up a slip sheet from our slip sheet magazine and place in between the layers.

Get Started

Robot Palletizing Wire Spools

Watch a Fanuc 420iF robot palletize wire spools with a Slip Sheet Pick and Place option.

The robot uses one of our custom-made End of Arm Tools with a slip sheet pick up option. We use a series of sensors to detect the spool and place them on a pallet. After a layer of wire spools are placed, the robot will pick up a slip sheet from our slip sheet magazine and place in between the layers.

Get Started

Increase Bags per Minute with Tandem Tool

Watch a tandem tool palletize wood pellets with a 430iW.The Tandem Tool Palletizer combines two End of Arm Tools into one to increase bagging speed. It works by feeding wood pellets through a hopper which feeds them into a rotating drum. This rotates the pellets around so that they fall onto a conveyor belt where they are collected into bags.The increase in bags per minute with a tandem tool because the machine can move faster and use a wider range of motion, allowing it to pack more material into each bag than a single operator.Get Started

Increase Bags per Minute with Tandem Tool

Watch a tandem tool palletize wood pellets with a 430iW.

The Tandem Tool Palletizer combines two machines into one to increase bagging speed. It works by feeding wood pellets through a hopper which feeds them into a rotating drum. This rotates the pellets around so that they fall onto a conveyor belt where they are collected into bags.

The increase in bags per minute with a tandem tool because the machine can move faster and use a wider range of motion, allowing it to pack more material into each bag than a single operator.

Get Started

Robot Cell with Tandem Tool and Pallet and Slip Sheet Dispenser

Watch a reconditioned Fanuc robot palletize using our tandem end effector tool running at approximately 20 bags per minute (BPM).

The Robot Cell consists of our two-in-one End of Arm Tool working independently together. We are able to program the 2-in-1 tool to operate separately which allows us to pick up two bags at once while still providing the freedom to rotate and drop each bag independently so we can ensure proper bag orientation for each bag recipe. We can also provide recipes on the HMI Touchscreen that will allow the Tandem Tool to pick up only one bag at a time if that is needed.

We offer a simple, selectable set of recipes that are pre-programmed on our HMI Touch Screen along with the inclusion of Pallet and Slip Sheet Controls on one common Touch Screen.

Get Started

Standard Clam Shell End of Arm Tool with Pallet in/Out Conveyors

Watch a Fanuc 410 4-axis robot palletize feed corn with pallet eject conveyors.

Our standard Ultra-Lite clam shell end-of-arm tool is used to pick and place 50lb bags of feed corn. In this layout, we use pallet in/out conveyors to feed empty pallets into the palletizing zone and eject the completed pallets out based on the recipe the operator is running. We have multiple Robotic System layouts with automatic pallet dispensers or in/out conveyors available to pick from.

Get Started

Standard Clam Shell End of Arm Tool with Pallet Conveyors

Watch a Fanuc 410 4-axis robot palletize feed corn with pallet eject conveyors.

Our standard Ultra-Lite clam shell end-of-arm tool is used to pick and place 50lb bags of feed corn. In this layout, we use pallet in/out conveyors to feed empty pallets into the palletizing zone and eject the completed pallets out based on the recipe the operator is running. We have multiple Robotic System layouts available to pick from.

Get Started

Robot Cell with Tandem Tool and Pallet Conveyors

Watch a tandem robot palletizer with a tandem tool running at 20 bags per minute (BPM).

The Robot Cell consists of two robots working together. Each robot holds a tool and a pallet conveyor. The first robot picks up a bag from the top of the stack and places it on the conveyor. Then the second robot takes over and places the next bag on the conveyor. This process continues until all the bags are placed on the conveyor.

Get Started

Robotic Palletizing: Kuka KR Titan Application

Watch a Kuka KR Titan Application Robot easily move heavy loads.

The KR1000 titan is a 6-axis industrial robot designed for handling large pallets. It is equipped with a high-performance servo-drive system and a robust control unit. This allows the KR1000 titan to handle loads up to 1,000 kg.

Get Started

Robotic Palletizing: Kuka KR Titan Application

Watch a Kuka KR Titan Application Robot easily move heavy loads.

The KR1000 titan is a 6-axis industrial robot designed for handling large pallets. It is equipped with a high-performance servo-drive system and a robust control unit. This allows the KR1000 titan to handle loads up to 1,000 kg.

Get Started